Arm Pipe’s 5-Layer Pipes

Considering the large costs of today’s buildings, planning to increase the lifespan of buildings seems essential. One of the most important factors to increase the lifespan of a building is its plumbing and installation system.

Along with the recent developments and the application of new technologies in the construction industry, the pipes used in the building have undergone a tremendous transformation. This development has been introduced with the supply of PERT-AL-PERT five-layer consolidated pipes with a lifespan of more than 50 years with a maximum operating temperature of 90 degrees Celsius.

The new generation of pipes, which are known as five-layer pipes, have quickly replaced metal and polymer pipes all over the world for reasons such as strength and durability, compliance with health standards, quick and easy installation, and reasonable prices.

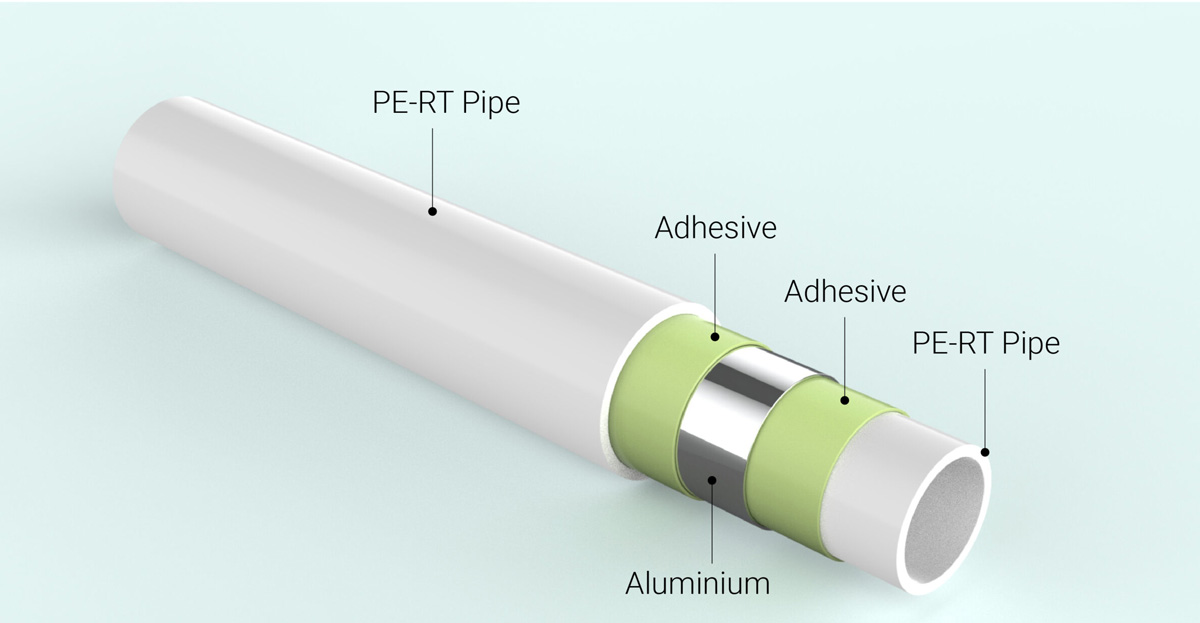

5-Layer Pipe structure

The five-layer pipes of Arm Pipe consist of two layers of PERT or PEX polymer, two layers of glue and one layer of aluminum.

The inner and outer layers are made of a special polymer based on polyethylene, which guarantees the resistance of the pipe against corrosion and sedimentation. The middle layer, which is aluminum metal, is welded lengthwise by overfap method with ultrasonic technology. Glue is used to combine two inner and outer layers of polymer to aluminum, which plays an important role in the integrity and resistance of the pipe.

5-Layer Pipe Application

Arm pipe’s five-layer pipes can be installed in hot and cold sanitary drinking water systems, central heating and cooling, underfloor heating and radiators, city water branches and used in the construction, food, marine, air and… industries. They are widely placed.

Advantages of 5-Layer Pipes

- Five-layered pipes do not rust, rot or deposit.

- They don’t have any problem with heat tolerance even continuously.

- Their expansion coefficient is low and almost equal to copper pipes.

- They are less economical due to the use of connections.

- Their waste is close to zero.

- Their pressure drop is low.

- Due to its lightness, it is easy and cheap to transport.

- They have more resistance than other pipes against construction settlements and earthquakes.

- It is resistant to most chemicals.

- The reliability coefficient of its connections is very high and is in harmony with the characteristics of the pipe.

- It is resistant to oxygen.