Test description

Tensile strength, which is measured with a tensile device, is the ability of polymers to withstand the maximum amount of tensile stress that they can withstand without failing. This point is when the material changes from elastic deformation to plastic deformation.

Tensile test is one of the most important and widely used polymers tests and plays an important role in the selection of materials for the production of various polymer products.

Tensile test measures the resistance to deformation against tension or pulling, and it is also possible to measure the strength of the weld. This test is performed for M-type pipes with polyethylene base.

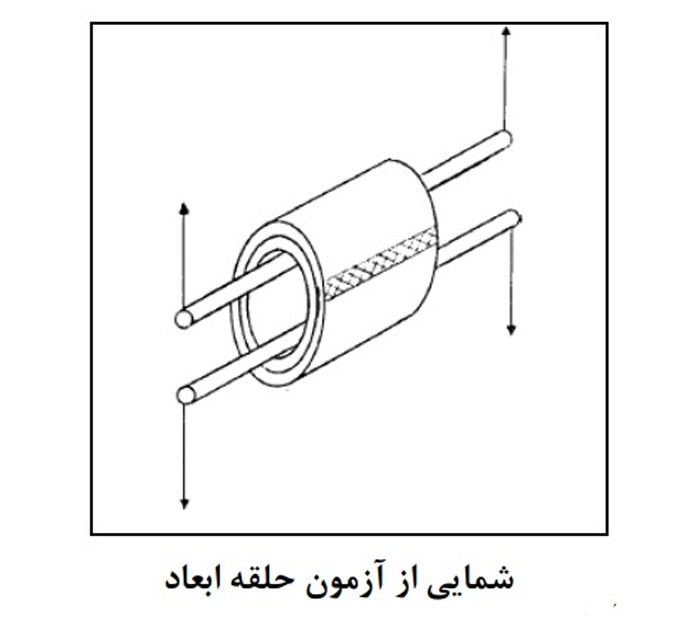

The test contains a piece of pipe with the length of 25±1 mm, which should be cut straight and perpendicular to the pipe axis. The number of samples is 15 and they are one after the other, which are drawn perpendicular to the weld seam at a speed of 50±2.5 mm/min according to the figure. The diameter of the rod holding the test piece should be at least 4 mm.

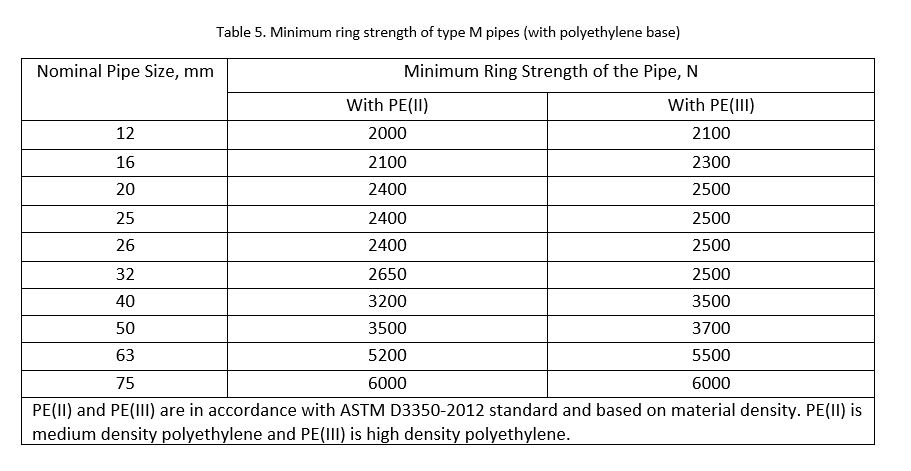

The minimum ring strength should be according to the table below.