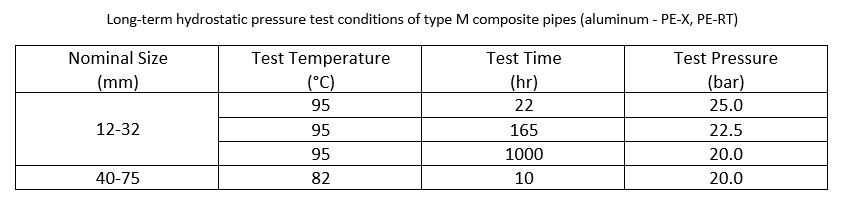

Hydrostatic Pressure Test

Those types of polymer pipes and connections such as polyethylene and polypropylene or PVC pipes in which fluids or water will pass through them with pressure, an important and vital test called resistance to hydrostatic pressure will be performed on them.

Failure to pay attention to the hydrostatic test in pipes or the resistance of pipes to hydrostatic pressure can lead to many injuries. Suppose a pipe is manufactured according to the specifications and is used at the maximum operating pressure, but the failure to perform the hydrostatic pressure test or a mistake in performing it has caused it to leak and burst after a period of use in the soil or buildings. has been A lot of money has to be spent to compensate for the damage caused. Therefore, by conducting hydrostatic pressure test in pipes and fittings, financial and even life damages can be avoided.