Test Method

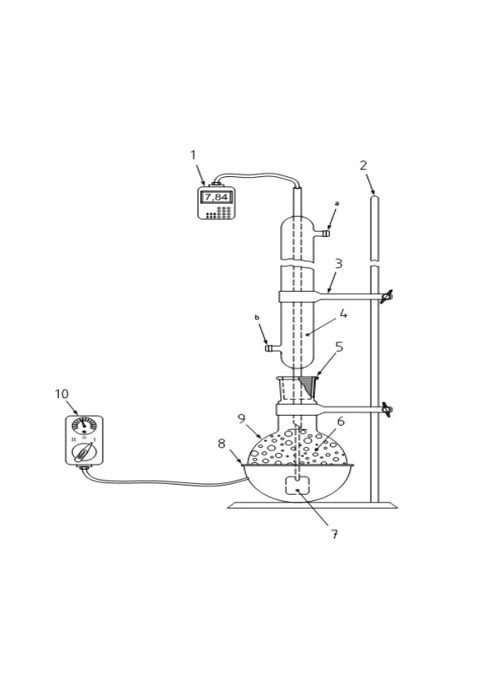

1. Weigh the clean and dry mesh cage and lid carefully.

2. Place the test in the mesh cage, put the lid on it and weigh the set carefully.

3. Place the mesh cage and the sample with the cap in the balloon and make sure that there is enough solvent

There is a solution for immersing the sample in such a way that the minimum ratio of solvent weight to sample weight is 200 to 1.

The solvent can be reused after distillation by adding one volume percent of antioxidant. At 140 degrees Celsius.

In case of waste, use a fresh or distilled solution.

4. Boil the solvent for a period of time to make sure of proper corrosion in it.

5. The mesh cage and its cover along with the remaining sample after the time mentioned in the previous step

Remove the solution.

Caution – Be careful when removing the mesh cage from the boiling solution

6. Dry the rest of the sample along with the net cage for 3 hours using one of the following methods:

a. By means of a vacuum oven, keeping at a temperature under vacuum with a minimum pressure of 0.85 bar (about an absolute pressure of 0.15 bar or less).

b. By means of a fan oven, with the possibility of proper extraction, placing in the temperature

7. Allow it to cool at room temperature. Then weigh the remaining (weight) net cage and cover and the remaining weight (weight) with 1 mg precision.